PPG’s SEM Products launches new texture refinishing products

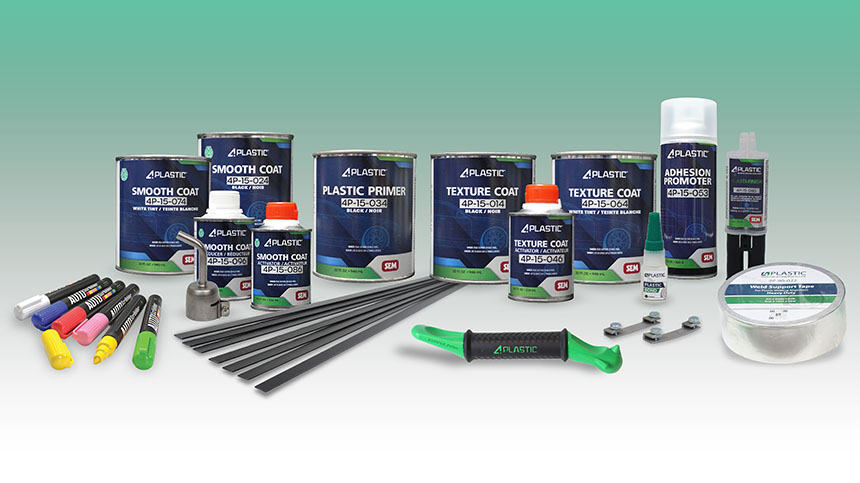

PPG has announced that its SEM Products business, in collaboration with 4Plastic, has launched a new generation of texture refinishing products engineered specifically for the repair of non-painted, textured plastic components.

The texture coatings system line has been launched in the US and Canada first and is designed to elevate the plastic repair process.

New texture refinishing products

Larry Trexler, PPG global allied products technical market support manager, Automotive Refinish, said: “As automakers increasingly replace traditionally painted panels with textured bare plastic external components, the collision repair industry needs solutions to accurately restore these surfaces after damage.

“It is a significant challenge for repair shops, insurers and OEM programmes, as textured component replacements often do not match the existing faded plastics on a vehicle, so the ability to repair and retexture them has become a high-value capability.”

The SEM and 4Plastic texture range directly addresses this need with advanced coatings formulated to replicate the most common OEM textures. Bodyshops can use the 4Plastic App so the right texture can be easily identified and matched for the repair.

The texture system demonstrated exceptional durability and performance in internal testing. Accelerated weathering tests verified environmental resistance, with only minor gloss changes that mirror natural OEM aging, confirming an OEM-grade finish built to endure everyday conditions. Adhesion testing confirms a strong, long-lasting bond, while abrasion and solvent resistance tests showed that the coating withstands real-world wear without damage or color transfer.

Fast application, predictable results

The products offer fast application, predictable results, and simplified training, allowing even entry-level technicians to achieve consistent finishes. This makes the repair of textured components both operationally efficient and commercially attractive, reducing unnecessary replacement costs and shortening cycle times.

Michael LoPrete, managing director of 4Plastic, said about the new texture refinishing products: “OEMs have moved decisively toward textured plastics as part of their design and manufacturing strategy, but the repair industry has not had an advanced system to restore those textures accurately until now. The SEM and 4Plastic range bring together scientific formulation, rigorous testing and practical usability, giving collision centers a true repair-first option for textured components. The ability to restore these parts rather than replace them not only reduces costs but also supports ongoing sustainability initiatives by preventing plastic waste and reducing parts-related emissions.”

The new line will be complemented by a range of tools and equipment designed to simplify and speed up plastic parts repair, including an innovative tool designed for pushing out dents and refining bodylines in plastic bumpers.